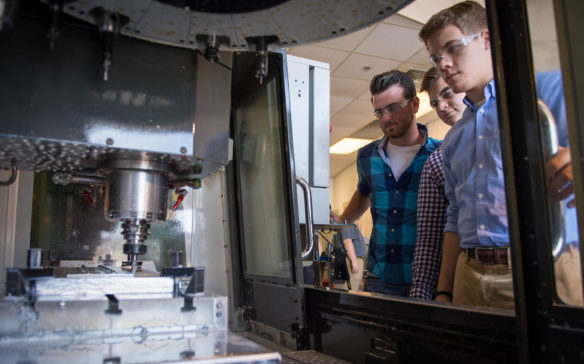

Breckinridge County Area Technology Center students, from left, Luke Mattingly, Brenden Kiper and Wyatt Lucas check on parts being machined with a water drill. The parts will be used in the air filtration system on the International Space Station as part of the school’s work with NASA’s HUNCH (High School Students United with NASA to Create Hardware) program.

Photo by Bobby Ellis, May 9, 2017

By Mike Marsee

mike.marsee@education.ky.gov

Three years into a partnership with NASA, students at Breckinridge County Area Technology Center are sending some of their handiwork into orbit for the first time.

Students in the computerized manufacturing and machining classes at Breckinridge County ATC have been making training hardware as part of High School Students United with NASA to Create Hardware (HUNCH) since 2014.

This past school year, students involved in the program took their work a step further when they were asked to manufacture parts that are to be used on the International Space Station (ISS) itself later this year. The parts are expected to be shipped to the ISS in November for use in the air filtration system in the crew’s sleeping quarters.

“As long as they’re happy with what we’re doing, I think they’ll keep using the school,” said Dean Monarch, an instructor whose students have been involved with the program since it was introduced at the school in 2014.

Bob Zeek, a project manager at NASA’s Marshall Space Flight Center in Huntsville, Ala., who is one of the founders of the HUNCH program, visits Breckinridge County ATC frequently and said he is very happy with what its students have done over the past three years.

“This program has improved by leaps and bounds,” Zeek said. “We came here with the expectation of having them build mockup crew training aids and they fulfilled both tasks we provided them that first year, so the second year we introduced some new tasks. Based on the quality of their work and the dedication, I saw a fit to have them work on these parts for flight.”

Dean Monarch, the machine tool technology instructor at Breckinridge County Area Technology Center, opens the door to a water drill used to machine parts students are manufacturing for the International Space Station. Students at the school study hardware designs sent to them by NASA and build hardware, create the programs that machine the parts and check the parts against NASA specifications.

Photo by Bobby Ellis, May 9, 2017

HUNCH was launched in 2003 to promote student interest in STEM fields, inspire the next generation of researchers and provide cost-effective hardware for NASA. It started with three schools, and it now includes 117 schools in 28 states. Breckinridge County ATC is the only school in Kentucky participating in the program.

Students study hardware designs sent to them by NASA and build hardware based on those designs, create the programs that machine those parts and make sure they meet NASA’s specifications.

Most of the hardware they build is used in training, but Zeek said there are more than 200 parts designed by HUNCH students in space, including cargo bags, galley tables and lockers.

Monarch, who along with John Whitfill teaches computerized manufacturing and machining at Breckinridge County ATC, said HUNCH has been tremendous for his students.

“I think the real world application has been very big,” Monarch said. “They’re not just making a part because the teacher said, ‘Make a part.’ They see something at the end of the line.

“It’s really beneficial for those that are going into engineering to have this hands-on experience, and for those that are going into industry to understand the engineering part of it.”

He said about 50 percent of the Breckinridge County students who worked on HUNCH projects last year were going into an engineering track after graduation. The other 50 percent or so were going directly into industry, many of them with the option to work as engineers after a few years of on-the-job experience.

The students’ work in high school could even lead to a job in the space program for those who are interested. Zeek said there are eight to 10 students from the HUNCH program working either with NASA or its contractors, and co-op opportunities are available as well

Wyatt Lucas, who graduated this spring and was one of about 15 Breckinridge County ATC students working in the HUNCH program last school year, said that work influenced his decision about what to do after he graduated.

“I had no idea what I wanted to do after college until I started taking these courses, and that kind of opened my eyes to this whole aspect of the world,” said Lucas, who plans to major in electromechanical engineering at Murray State. “It could take me into manufacturing, and with a background in machining, I have a different perspective than most engineers might have. It opens me up to a lot of things, actually.”

Luke Mattingly, another recent graduate, said students in the program had an additional incentive to succeed as well.

“If we were to fail, it comes back on the school. But if we succeed, it gives us more jobs like this in the future,” Mattingly said.

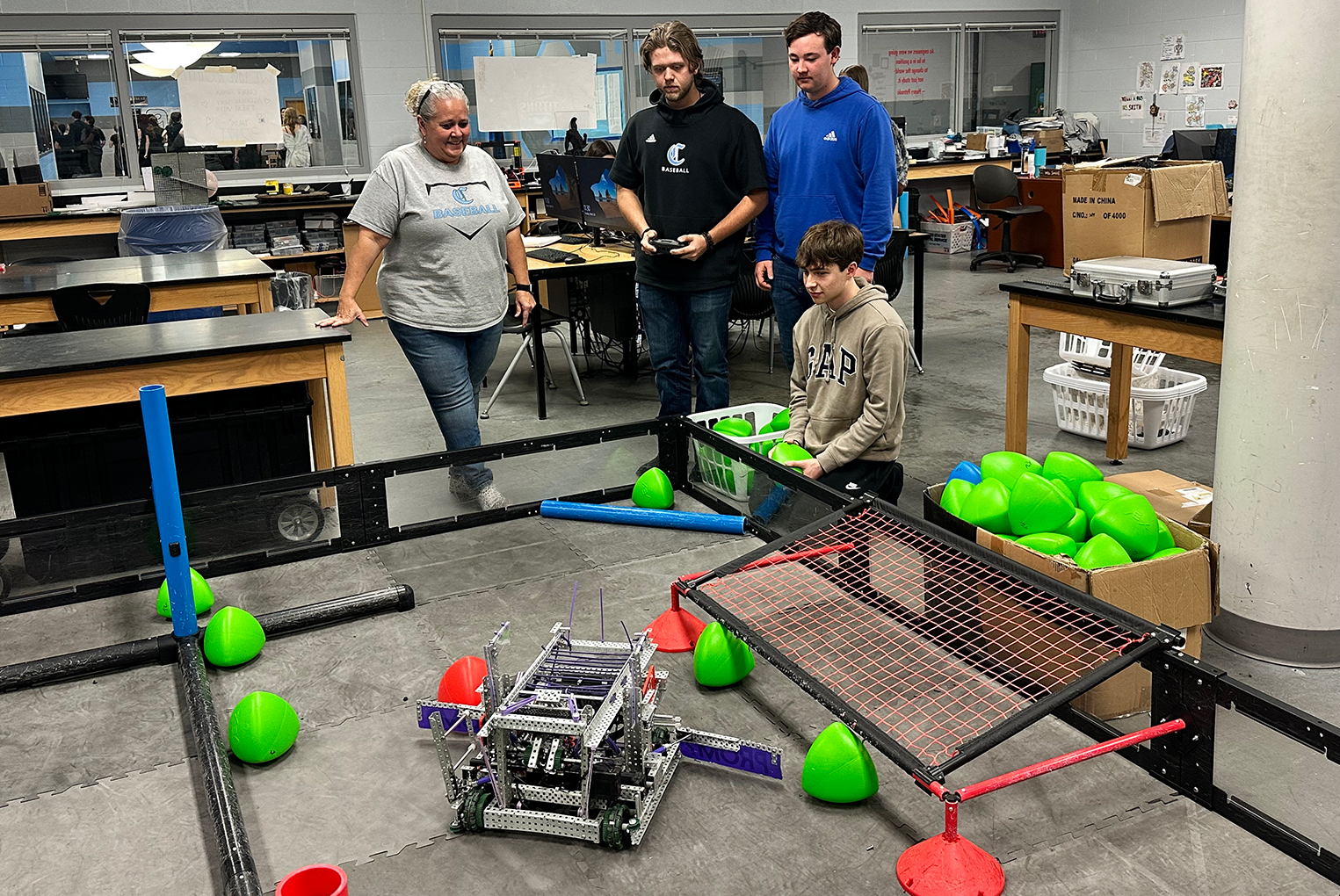

Brenden Kiper, a student at Breckinridge County Area Technology Center, holds a part that will fit over a filter on the International Space Station. The school has been working with NASA’s HUNCH program since 2014, but this is the first project in which students’ work will be used in space.

Photo by Bobby Ellis, May 9, 2017

In the most-recent job, students were building parts that will prevent lint from slipping through the air filtration system on the ISS. The lint has been building up around electronic parts and astronauts on board the station haven’t been able to do anything about it.

“Without being able to send up a whole new system, they needed to come up with an idea on how to improve the lint catchers,” Monarch said. “They gave it out to several schools to prototype. Our prototype was turned in first and was most accurate, so we got the bid to make all the rest of them.”

Breckinridge County ATC students built parts in two different sizes that will fit over the existing filters. They will send six sets of four parts each to the ISS.

“Right now the astronauts are spending about 30 hours a month cleaning lint catchers, and this should cut it down to about four hours a month,” Monarch said.

“It’s really good because it’s project-based learning. They’re working with an engineer. They find problems with a blueprint, they call the engineers in Houston, and a week later we might get a revised blueprint.”

Monarch said students had to write “foolproof” programs that could be used by different students during different class periods.

“It’s sort of like a change of shift in industry,” he said. ”If were running something new and we didn’t communicate, we made mistakes.”

The students faced a time crunch as well. They were first contacted in November, but they didn’t get final approval for the project from NASA until May 2, and they were trying to finish building the parts by the end of the school year.

At a reception recognizing the students who took part in the program during the year, Zeek had them sign a locker that will fly to the ISS in October. Those who build hardware for space flight frequently sign their work, but the parts the Breckinridge County ATC students made were too small to sign.

“To get your signature on flight hardware is a pretty big thing,” Zeek said. “The crew members will take a picture with this in space.”

Of course, being able to say they built hardware being used in space is also a significant accomplishment for a high school student.

“It just makes you feel like you accomplished something that most people our age don’t have a chance to do,” Mattingly said.

Zeek said that should stand out on a resume.

“They’re going to take the name NASA and the fact that they worked on International Space Station flight hardware and put that on their resume, and I tell them to bold it out because it’s going to pop,” Zeek said.

“I would have loved to have had on my resume when I graduated high school at 18 that I produced parts that are now on the International Space Station,” Monarch added.

However, Zeek said the HUNCH program’s strongest asset is that it gets students out of their textbooks and into a hands-on work environment.

“It gives them live work and gives them resume material,” he said.

MORE INFO …

HUNCH

Dean Monarch dean.monarch@meade.kyschools.us

Leave A Comment